| Danner

process equipment for glass tubing drawing |

|

��

Glass

tubing is drawn out from the tip of the sleeve

|

| 1. |

Preface |

|

Danner

process, which is a horizontal glass tubing technology, is the

most usual choice for soda-lime, lead and borosilicate glass

tubing drawing. This process provides good accuracy in diameter,

thickness; bow and ovality as well as lopside, thus the most glass

tubing production lines in the world were and are equipped with

Danner process and its machines.

Beijing

Quarts V. Glass Co., Ltd. supply either single machine or complete

tubing drawing line, meanwhile Vello process equipment and whole

line are also available to be provided. |

|

��

2. |

��

Components

of Danner Process Equipment |

|

The

Danner process consists of a trough at the end of forehearth, a

Muffle in which a hollow refractory mandrel aslant installed and

called as Sleeve, a Sleeve driver, tubing running alley and a

Danner drawing machine together with cutter(s) as well as a

precise cutting & glazing machine. The accessories of Danner

tubing line are combustion system for Muffle, temperature control

system of trough and Muffle as well as dimensions detectors for

outside diameter and wall thickness, glass defects some cases. |

|

��

3. |

��

Muffle |

|

|

The

Muffle is a kind of oven with two layers, the first layer is made

of Silicon Carbon (SiC) plates that form an oval shape chamber, in

center of which the sleeve locates. The molten glass from

forehearth through a refractory gate flows out of the trough and

falls down as glass ribbon to the sleeve. |

|

��

4. |

��

Sleeve

part |

|

A

refractory mandrel plays a role of the sleeve that fixes on the

sleeve shaft. The size of sleeve depends on the size of the tubing

to be drawn. The sleeve shaft is a bigger and longer enough

heat-resistant steel axle with a straight hole in the center for

inflating air.

Material: Sillimanite

Dimension: Length

1500mm

Diameter:270, 300, 330mm |

|

|

��

5. |

��

Sleeve

driver |

|

The

sleeve driver is used to drive the sleeve shaft with sleeve

rotating.

Its main body is water cooled, the sleeve shaft in it is driven

by a motor and the worm-gear box. There are several adjusting

parts on the sleeve driver respectively, at the base of the

support frame of the driver there are hydraulic cylinders to move

the sleeve driver up/down and left/right at the initial stage of

installation.

Main drive: 3.0Kw, 380V, 50Hz

Speed: 4 rpm (min.)�C15 rpm (max.)

Diameter of chuck: 100 mm

(75mm also available)

Number of rotation: 4�C15 rpm, adjustable

Adjusting angle: 0��C15��, adjustable

Vertical stroke: 510 mm, adjustable

Back and forth stroke: 260 mm, adjustable

Lateral stroke: ��70 mm, adjustable

|

|

��

6. |

��

Tubing

Running Alley |

|

The

tubing running alley comprises two parts. The

insulation cover made of steel plates eliminates the influence of

environment temperature. The cover and pit make a closed

tunnel to be the first part. The other part is running alley that

holds the glass tubing for a relative long distance mostly in the

closed cases. Many rollers inside of the alley are free rotating

by means of air bearings and playing the role of the tubing

brackets.. |

|

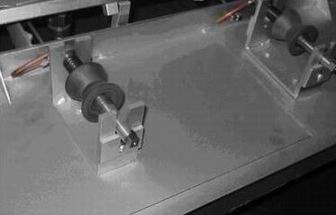

��

Tubing Running Alley and X-Y laser OD

detector

Rollers inside of the alley |

|

��

7. |

��

Drawing

Machine (Danner Machine) |

|

The

Drawing machine usually includes cutting machine, which can be

driven by the same motor used for the drawing machine or an

independent motor. The drawing motor drives several rollers that

are located at two layers shown as the photo below. The both upper and lower

belts ring are hooped on the rollers. The tubing is running

forward in the gap between both rotating belts. The rotating of

the belts always enables tubing moving to the cuter.

At the entrance of the drawing machine there are three guide

rollers, two vertical rollers and one horizontal

roller guides the tubing to the gap of belts.

The

cutter can be single or double according to tube size and the line

speed of tubing drawing.

After

cutting it is a sorting machine to reject NG tubes based on laser

OD detector signals in the case of over tolerance of outside

diameter.

Main drive unit: 3.0Kw, 380V, 50Hz

Glass tubing diameter:4.0�C40mm

Drawing speed:25-200mm/min.

Cutting length:1000�C1800mm |

|

��

The

Drawing machine following with cutter and sorting machine |

|

��

8. |

��

Precise

cutting and Glazing |

|

The

tubes after sorting are qualified tubes in diameter, which are

moving to re-cutting and glazing machine through the front

conveyer (three segments) with line up machine.

The re-cutting is done by several pairs of burners at the both

ends of the machine, i.e. both tube ends together are precisely

cut with a pair of sharp and thin discs made of special steel. The

cut tubes then move to be glazed by 6 pairs of glazing burner.

After glazing the hot tubes should be cooling down on a cooling

conveyer, then the tubes can be packed.

Main drive unit: 1.5Kw ´2, 0.4 KW 380V,

50Hz

Length:1200mm�C1800mm

Precise cut and glazed glass tubing diameter:10�C40mm

Cutting length:1200�C1700mm

Full length of the machine:11m

We

also supply the front conveyers installed before precise cutting

machine and

cooling conveyer after glazing machine. |

|

��

9. |

��

Electric

part |

|

(1)

Automatic control system

�� Muffle roof temperature control system

�� Muffle chamber temperature control system

�� Inflating air pressure control system

(2)

Automatic sorting system

Laser O.D. measuring system and sorting system

General type (single direction) and X-Y type are available

(3)

Automatic synchronizing system for any tubing specification

All motors of conveyers and re-cutting &

glazing machine after cutting should be synchronized to ensure no

touch between tubes on the conveyers to avoid scratches.

(4)

Monitoring system

Tubing catenary monitoring system by ITV.

(5)

Measuring system

�� Measuring speed of sleeve driver

�� Measuring speed of drawing machine

�� Measuring cut numbers, NG counter, OK counter

after the first cutting

�� Measuring Muffle temperature at 5 points

�� Measuring

inflating air pressure |

|

|